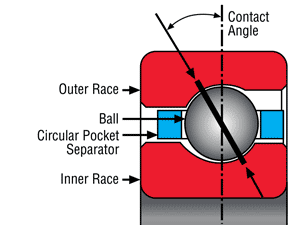

Kaydon Reali-Slim® Type A angular contact ball bearings have sufficient diametral clearance to produce a substantial angle of contact for resistance to axial load. This contact angle is 30° in the standard bearing. Extra deep ball grooves are used (25% of ball diameter).

The distinguishing feature of Kaydon type A thin section bearing lies in the method of assembly. One ring, usually the outer, is counter-bored to reduce one shoulder of the raceway to the extent that, with the assistance of a temperature differential between the two rings, the outer ring can be installed over the inner race, ball, and separator assembly. This provides a non-separable bearing capable of carrying greater radial loads while resisting a substantial axial force in one direction. With an axial force applied, the faces of the inner and outer rings are approximately flush, to minimize preload adjustments.

This assembly method permits the use of a greater complement of balls than is possible in Kaydon type C Conrad assembly bearing, and together with the sizable contact angle, gives the type A bearing its greater thrust capacity.

Because of its unidirectional thrust capability, this Kaydon bearing should be mounted opposed to another bearing such that an axial force is present to establish and maintain the contact angle and to minimize axial movement under reversing thrust loads.

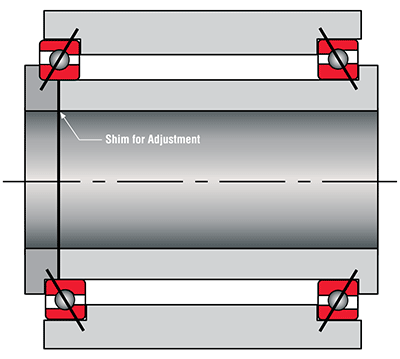

In a back-to-back mounting, the bearings are adjustable through the inner races by use of shims under the inner race clamping ring and the lines of contact converge outside of the bearings. Sufficient shim thickness is provided initially to allow axial movement of the shaft relative to the housing. The total axial movement can then be measured and the shim thickness reduced by the amount of movement plus any additional amount desired for preload. When two bearings are opposed to each other to the extent that all internal clearance is removed and elastic deformation occurs between the balls and raceways, the bearings are said to be 'preloaded.'

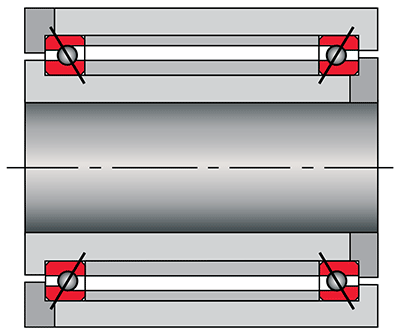

When bearings are mounted face-to-face, the contact lines converge inward. Spacers are used between both the inner and outer races and adjustment is possible by varying the length of one spacer relative to the other. Normally, however, the spacers are equal in length and the bearings are furnished as a matched pair with a predetermined internal fit. If the outer race spacer were removed from this assembly, the bearings could be adjusted by use of shims under the outer race clamping ring.

Duplexed bearings

Kaydon type A thin section bearings are furnished as matched sets—available direct from the factory—when they are to be mounted adjacently or with equal length inner and outer race spacers. When required, Kaydon can supply assemblies with matched ground spacers. Duplexed bearings are supplied in back-to-back, face-to-face, or tandem arrangements. Sets of three, four or more bearings can also be matched where conditions require additional capacity and there is insufficient space radially for larger bearings.

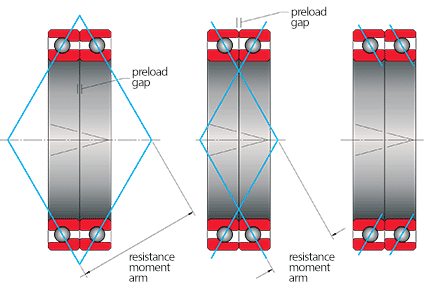

Back to back (left)

Face to face (center)

Tandem (right)

Kaydon bearings in these sets are matched within close limits for size of bore and outside diameter. Each set is marked with a 'V' across the bores and outside diameters at the high point of radial runout to indicate the proper orientation of the races at installation.

Bearings provided in back-to-back and face-to-face arrangements are normally furnished with the race faces ground, to provide preload when installed. To accomplish this, a gap is provided between the inner races of the back-to-back pair and between the outer races of the face-to-face pair. When the bearings are installed and clamped axially, the gap is closed, producing a preload on the bearings.

A back-to-back arrangement offers greater rigidity under moment loading and should be used when the space between single bearings is small or when a single pair of adjacent bearings is employed.

A face-to-face arrangement is more tolerant of misalignment between the shaft and housing and should be considered when there are multiple pairs of bearings along an axis. When single bearings are mounted face-to-face, they must be spaced sufficiently to provide resistance to moment load. If required, a face-to-face pair can be mounted in conjunction with another bearing in a 'fixed-float' arrangement, with the pair in the fixed position.

Tandem bearing sets have single direction thrust capacity and must be mounted opposed to another bearing or set.

When applying catalog load ratings to matched sets, the total radial capacity is considered equal to the single bearing radial rating multiplied by N0.7, where N is the number of bearings in the set. The thrust capacity in each direction is considered equal to the single bearing thrust rating multiplied by N0.7, where N is the number of bearings resisting thrust in that direction.

Unless specifically requested, the outboard faces of bearing sets are not controlled. If outboard face flushness is required for preload purposes, universally ground bearings should be considered. On universally ground bearings, both inboard and outboard faces are matched under a specified gage load to control preload and allow for mounting orientation flexibility.