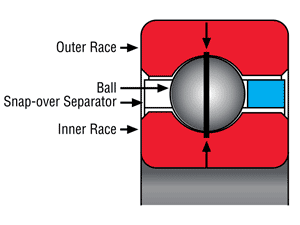

Kaydon Reali-Slim® type C radial contact ball bearing is a single-row radial ball bearing with extra deep ball grooves in both rings (groove depth = 25% of ball diameter). This bearing is typically assembled by eccentric displacement of the inner race within the outer race, which permits insertion of about half of a full complement of balls. After insertion of the balls, the races are positioned concentrically and the balls are spaced about the entire circumference for assembly of the separator. This method of assembly is commonly termed 'Conrad assembly.'

An alternate method of assembly is to insert balls through a 'filling slot' made by notching the raceway shoulder of one or both races. This method permits assembly with up to a full complement of balls for additional load capacity. With a filling slot, both the dynamic radial and thrust capabilities are impaired by the interruption of the ball contact path, and speed of rotation must be limited.

Kaydon type C thin section bearings perform best with a small amount of diametral clearance (the clearance between the balls and races. Standard bearings are supplied with clearances that allow for:

- interference fitting between bearing races and mounting members

- differential thermal expansion or contraction of steel races

- misalignment between shaft and housing and other factors may require the clearance to be adjusted accordingly

Kaydon type C radial contact bearing is designed to have ball-to-race contact in the plane of the ball centers when pure radial load is applied and thrust forces are absent. Necessary diametral clearance may be increased or decreased to meet operating conditions.

While designed primarily for radial load application, the Conrad assembly type C bearing will accept some axial (thrust) load in either direction. Its ability to resist axial load, however, is dependent upon the amount of clearance in the bearing after installation. It is this clearance which allows the balls, under axial load, to contact the races at an angle, thereby offering resistance to such load. In the case of a type C bearing with a filling slot, the notches interrupt the ball contact paths under axial load, minimizing the dynamic thrust capability. Where axial load is present, therefore, rotation of the filling slot bearing must be restricted.

By increasing the diametral clearance beyond the standard amount, the type C bearing can have a greater angle of contact under axial load, and thus greater thrust capacity. In this case, the bearing should be adjusted against another bearing of similar construction to reduce axial movement under reversing thrust forces. Used in this manner, the bearing is essentially an angular contact rather than a radial contact bearing.