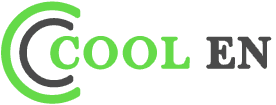

THK caged ball linear motion guide have caged ball. the use of a ball cage allows lines of evenly spaced balls to circulate, thus to eliminate friction between the balls.

In addition, grease held in a space between the ball circulation path and the ball cage (grease pocket) is applied on the contact surface between each ball and the ball cage as the ball rotates, forming an oil fi lm on the ball surface. As a result, an oil fi lm is not easily broken.

Advantages of THK caged ball LM guide

- The absence of friction between balls, together with increased grease retention, achieves long service life and long-term maintenance-free (lubrication-free) operation.

- The absence of ball-to-ball collision achieves low noise and acceptable running sound.

- The absence of friction between balls achieves low heat generation and high speed operation.

- The circulation of lines of evenly spaced balls ensures smooth ball rotation.

- The absence of friction between balls allows high grease retention and low dust generation.

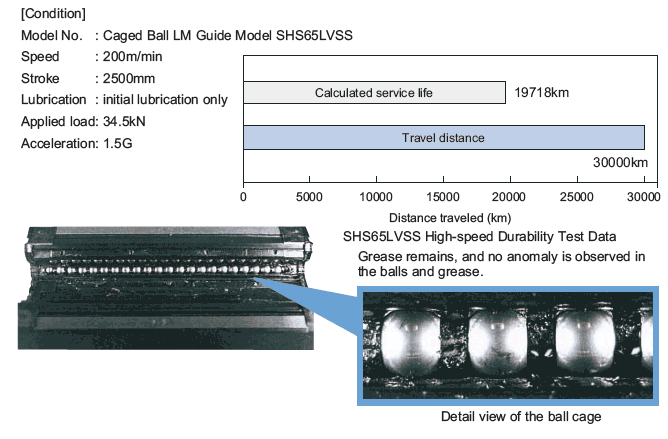

Long Service Life and Long-term Maintenance-free Operation]

Use of a ball cage eliminates friction between balls and increases grease retention, thus to achieve long service life and long-term maintenance-free operation.

Low Noise, Acceptable Running Sound

Since the ball circulation path inside THK LM block is made of resin, metallic noise between balls and the LM block is eliminated. In addition, use of a ball cage eliminates metallic noise of ball-to-ball collision, allowing a low noise level to be maintained even at high speed.

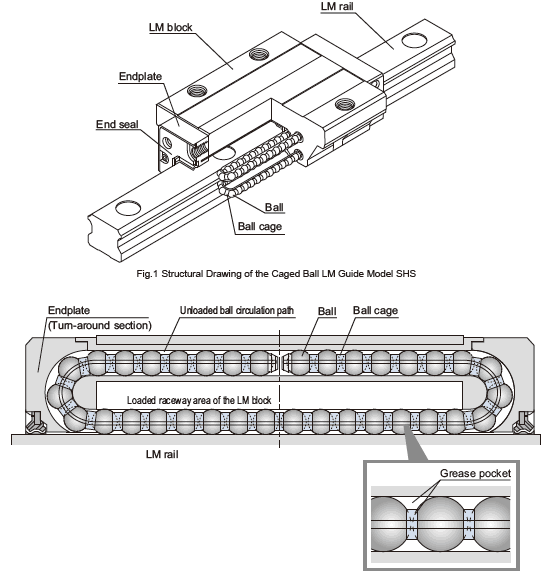

Comparison of Noise Levels between Caged Ball LM Guide #35 and Full-Ball Type #35

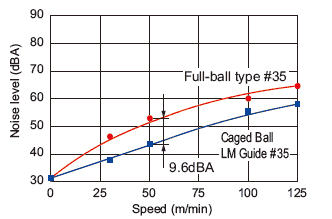

Comparison of Noise Levels between Caged Ball LM Guide #35 and Full-Ball Type #35 (at speed of 50 m/min)

High Speed

Since use of a ball cage eliminates friction between balls, only a low level of heat is generated and superbly high speed is achieved.

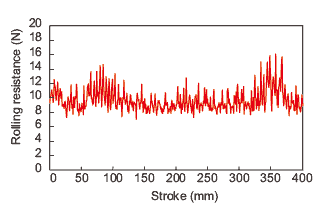

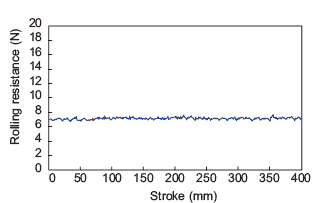

Smooth Motion

Use of a ball cage allows the balls to be uniformly aligned and prevents a line of balls from meandering as they enter the LM block. This enables smooth and stable motion to be achieved, minimizes fl uctuations in rolling resistance, and ensures high accuracy, in any mounting orientation.

Rolling Resistance Fluctuation Data with Full-Ball Type #25 (Vertical-use feeding speed: 1 mm/s)

Rolling Resistance Fluctuation Data with Caged Ball LM Guide #25 (Vertical-use feeding speed: 1 mm/s)

Low dust generation

In addition to friction between balls, metallic contact has also been eliminated by using resin for the through holes. Furthermore, the Caged Ball LM Guide has a high level of grease retention and minimizes fl y loss of grease, thus to achieve superbly low dust generation.