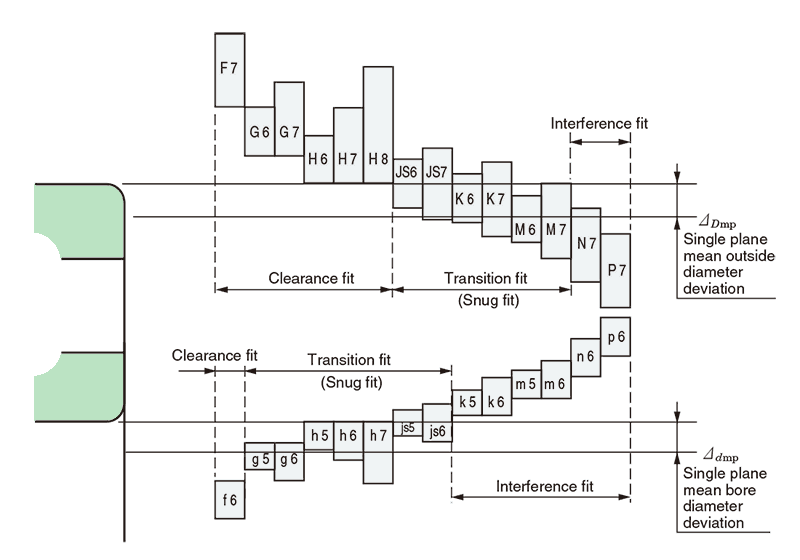

Fits for rolling bearings are typically specified with standard tolerance classes for holes and shafts as described in ISO 286-2. As bearings are typically manufactured to ISO tolerances, the selection of the tolerance class for the bearing seat determines the fit. For rolling bearings, inner and outer rings are fixed on the shaft or in the housing so that relative movement doesn't occur between fitting surfaces during operation or under load. This relative movement between the fitting surfaces of the bearing and the shaft or housing can occur in a radial direction, an axial direction, or in the direction of rotation. Types of fitting include tight, transition and loose fitting, which may be selected depending on whether or not there is interference.

The most effective way to fix the fitting surfaces between a bearings's raceway and shaft or housing is to apply a tight fit. The advantage of this tight fit for thin walled bearings is that it provides uniform load support over the entire ring circumference without any loss of load carrying capacity. However, with a tight fit, ease of installation and disassembly is lost; and when using a non-separable bearing as the floating-side bearing, axial displacement is not possible. For this reason, a tight fit cannot be recommended in all cases.

Importance of proper fits

In some cases, improper fit may lead to damage and shorten bearing life, therefore it is necessary to make a careful invetigation in selecting a proper fit. Some of the bearing failure caused by improper fit are listed below.

- Raceway cracking, early flaking and displacement of raceway

- Raceway and shaft or housing abrasion caused by creeping and fretting corrosion

- Seizing caused by negative internal clearances

- Increased noise and deteriorated rotational accuracy due to raceway groove deformation