Rolling bearings are available in a variety of types, configurations, and sizes. When selecting the correct bearing for your application, it is important to consider several factors, and analyse in various means.

Usually, a bearing type is provisionally chosen considering the operation conditions, mounting arrangement, ease of mounting in the machine, allowable space, cost, availability, and other factors.

Then the size of the bearing is chosen to satisfy the desired life requirement. When doing this, in addition to fatigue life, it is necessary to consider grease life, noise and vibration, wear, and other factors.

There is no fixed procedure for selecting bearings. It is good to investigate experience with similar applications and studies relevant to any special requirements for your specific application.

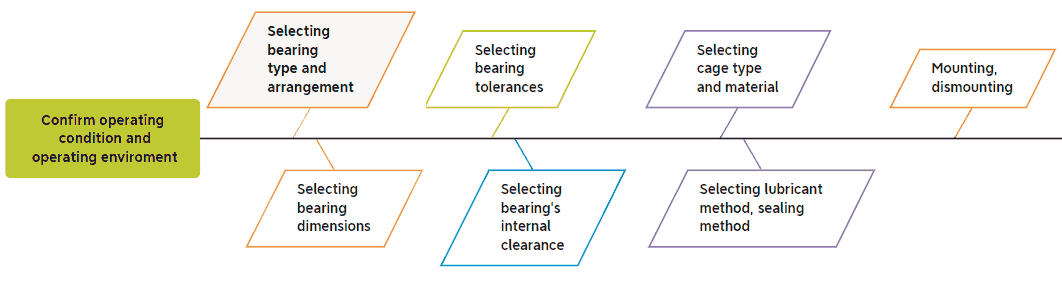

As a general guideline, the basic procedure for selection the most appropriate bearing is as follow.

An example of the bearing selection procedure

1, Confirm operating conditions and operating environment

- Operating conditions and required performance

- Environmental conditions

- Dimensions of shaft and housing

- Bearing mounting location

- Bearing load

- Rotational speed

- Temperature

2, Selecting bearing type and arrangement

- Allowable space

- Magnitude and direction of loads

- Vibration and shock

- Operating speed, maximum speed

- Bearing tolerances

- Misalignment of inner and outer rings

- Fixing in axial direction and mounting arrangement

- Ease of bearing mounting and dismounting

- Friction torque

- Required rigidity

- Availability and cost

3, Selecting bearing dimensions

- Expected life of machine

- Dynamic and static equivalent loads

- Speed

- Allowable static load factor

- Allowable axial loads

- Allowable space

4, Selecting bearing tolerances

- Running accuracy

- Rotational speed

- Torque fluctuation

5, Selecting bearing's internal clearance

- Fitting

- Operating conditions

- Magnitude and characteristics of lads

- Temperature range

- Materials, size, tolerance of shaft and housing

- Difference in temperature between inner and outer rings

- Speed

- Misalignment of inner and outer rings

- Amount of preload

- Rotational speed

6, Selecting cage type and material

- Speed

- Noise

- Operating temperature

- External vibration and shock

- Rapid acceleration and deceleration

- Momentary load and misalignment

- Environment (seawater, vacuum, gases, chemicals, etc.)

7, Selecting lubricating method, sealing method

- Operating temperature range

- Speed

- Lubricating methods

- Type of seals

- Maintenance and inspection intervals

8, Examination of ease of mounting, dismounting

- Procedure for mounting and dismounting

- Necessary equipment

- Dimensions affecting mounting.