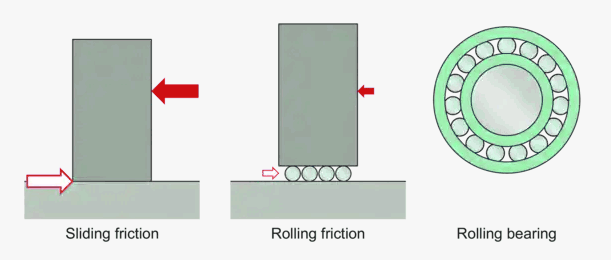

Rolling bearings support and guide, with minimal friction, rotating or oscillating machine elements - such as shafts, axles or wheels - and transfer loads between machine components Rolling bearings provide high precision and low friction and therefore enable high rotational speeds while reducing noise, heat, energy consumption and wear They are cost- effective and exchangeable machine elements that typically follow national or international dimension standards

The two basic types of rolling element distinguish the two basic types of rolling bearing:

- Ball → ball bearing

- Roller → roller bearing

Balls and rollers are different in how they make contact with the raceways.

Balls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.

Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.

Rolling bearings are classified into two groups based on the direction of the load they predominantly accommodate:

- Radial bearings accommodate loads that are predominantly perpendicular to the shaft. Some radial bearings can support only pure radial loads, while most can additionally accommodate some axial loads in one direction and, in some cases, both directions.

- Thrust bearings accommodate loads that act predominantly along the axis of the shaft. Depending on their design, thrust bearings may support pure axial loads in one or both directions, and some can additionally accommodate radial loads (combined loads). Thrust bearings cannot accommodate speeds as high as same-sized radial bearings.

Rolling bearings are used in all kinds of machinery such as:

- trains

- airplanes

- washing machines

- refrigerators

- air conditioners

- vacuum cleaners

- photocopy machines

- computers

- satellites

Bearings enhance the functionality of machinery and help to save energy. Bearings do their work silently, in tough environments, hidden in machinery where we can't see them. Nevertheless, bearings are crucial for the stable operation of machinery and for ensuring its top performance.

History of rolling bearings

The principle of bearings was known to the ancients, and they were used around B.C. 8 th century in ancient Mesopotamia.The illustration is a replica of a relief depicting construction in ancient Mesopotamia.

Later, that famous genius of the Renaissance, Leonardo da Vinci, came up with an idea for a structure that is remarkably similar to modern uses of bearings. The machine-based civilization that was born in the Industrial Revolution of the 18th century led to the development of modern bearings.

Bearings have been developed and improved in a global environment, and results from research into further reducing friction are accumulating all the time, continually anticipating the needs of the times. The ongoing challenge remains. To:

- reduce weight

- increase compactness

- lengthen life

- reduce energy requirements

- reduce the impact on the environment