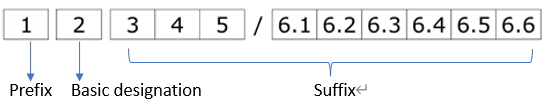

The designations of most SKF bearings follow a system that consists of a basic SKF designation with or without one or more prefixes and suffixes. Prefixes and suffixes provide additional information about SKF bearing.

- Prefixes are mainly used to identify components of a bearing. They can also identify bearing variants.

- Suffixes identify designs or variants, which differ in some way from the original design or from the current basic design. The suffixes are divided into groups.

1: Prefixes

2: Basic designation

3: Suffix - Internal design

4: Suffix - External design (seals, snap ring groove, etc.)

5: Suffix - Cage design

6.1: Suffix - Materials, heat treatment

6.2: Suffix - Tolerance, clearance, preload, quiet running

6.3: Suffix - Bearing sets, matched bearings

6.4: Suffix - Stabilization

6.5: Suffix - Lubrication

6.6: Suffix - Other variants

SKF bearing prefixes

D/W

Stainless steel, inch dimensions

ICOS-

Oil sealed bearing unit

W

Stainless steel, metric dimensions

WBB1

Stainless steel, metric dimensions, not in accordance with ISO dimension series

ALS

Inch bearing

AMS

Inch bearing

L

Separate inner or outer ring of a separable bearing

R

Inner or outer ring with roller and cage assembly of a separable bearing

R

Bearing without an inner ring

J

Metric bearing following the ABMA designation system (ANSI/ABMA Std. 19.1)

T

Metric bearing in accordance with ISO 355

BS2-..

Bearing, designated by a drawing number

ZE

Bearing with SensorMount feature

GS

Housing washer

K

Cylindrical roller and cage thrust assembly

WS

Shaft washer

SKF bearing suffixes

SKF suffix - Internal design

E, EC

Optimized internal design

A

30° contact angle

AB

20° contact angle (inch bearing)

AC

25° contact angle

B

40° contact angle

A

No filling slots (for SKF double row angular contact ball bearing)

D

Two-piece inner ring

CV

Modified internal design, full complement roller set

B

Steep contact angle (for SKF tapered roller bearing)

BC

Bearing for wind turbine main shafts with roller-guided cast iron cage

CA, CAC

Retaining flanges on the inner ring, guide ring centred on the inner ring, machined brass cage

CC(J), CJ

Flangeless inner ring, guide ring centred on the inner ring, two stamped steel cages

CCJA, EJA

Flangeless inner ring, guide ring centred on the outer ring raceway, two stamped steel cages

SKF suffix - External design

N

Snap ring groove in the outer ring

NR

Snap ring groove in the outer ring, with snap ring

N1

One locating slot (notch) in one outer ring side face

N2

Two locating slots (notches) in one outer ring side face, 180° apart

R

Flanged outer ring

-RS1, -2RS1

Contact seal, NBR, on one or both sides

-RS2, -2RS2

Contact seal, FKM, on one or both sides

-RS5, -2RS5

Contact seal, HNBR, on one or both sides

-RSF, -2RSF

Contact seal, NBR, on one or both sides

-RSH, -2RSH

Contact seal, NBR, on one or both sides

-RSH2, -2RSH2

Contact seal, FKM, on one or both sides

-RSL, -2RSL

Low-friction seal, NBR, on one or both sides

-RZ, -2RZ

Non-contact seal, NBR, on one or both sides

-Z, -2Z

Shield on one or both sides

-2ZS

Shield on both sides, held in place by a retaining ring

-2LS

Contact seal on both sides

-CS, -2CS

Contact seal, NBR, on one or both sides

-CS2, -2CS2

Contact seal, FKM, on one or both sides

-CS5, -2CS5

Contact seal, HNBR, on one or both sides

ADA

Modified internal design and standard PUR seal (for NNF 50 series)

ADB

Modified internal design and seal (for NNF 50 series)

DA

Modified internal design and standard PUR seal (for 3194.. series)

X

Boundary dimensions changed to conform to ISO

CA

Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have axial internal clearance smaller than Normal (CB).

CB

Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have Normal axial internal clearance.

CC

Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have axial internal clearance greater than Normal (CB).

B

Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have axial internal clearance.

GA

Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have light preload.

GB

Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have moderate preload.

GC

Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have heavy preload.

CB

Controlled axial internal clearance (for SKF double row angular contact ball bearing)

K

Tapered bore, taper 1:12

K30

Tapered bore, taper 1:30

AS..

Outer ring with lubrication hole(s), the number following indicates the number of holes

ASR..

Outer ring with annular groove and lubrication hole(s), the number following indicates the number of holes

IS..

Inner ring with lubrication hole(s), the number following indicates the number of holes

ISR..

Inner ring with annular groove and lubrication hole(s), the number following indicates the number of holes

Z

Combined needle roller bearing, factory greased thrust bearing with a cover without lubrication holes over the outside diameter

R

Flanged outer ring (for SKF tapered roller bearing)

SKF suffix - Cage design

J

Stamped steel cage, ball/roller centred

JA

Sheet steel cage, outer ring centred

JB

Sheet steel cage, inner ring centred

M

Machined brass cage, ball/roller centred; different designs or material grades are identified by a number following the M, e.g. M2

MA(S)

Machined brass cage, outer ring centred. The 'S' indicates a lubrication groove in the guiding surface.

MB(S)

Machined brass cage, inner ring centred. The 'S' indicates a lubrication groove in the guiding surface.

TN

PA66 cage, ball centred

TN9

Glass fibre reinforced PA66 cage, ball/roller centred

TNH

Glass fibre reinforced PEEK cage, ball/roller centred

F

Machined steel cage, ball centred

F3

Machined spheroidal cast iron cage, shaft washer centred

FA

Machined steel cage, outer ring centred

FR

Pin-type steel cage, pierced rollers

P

Glass fibre reinforced PA66 cage, ball/roller centred

PA

Glass fibre reinforced PA66 cage, outer ring centred

PH

Glass fibre reinforced PEEK cage, ball/roller centred

PHA

Glass fibre reinforced PEEK cage, outer ring centred

Y

Stamped brass cage, ball centred

L

Machined light alloy cage, roller centred

LA

Machined light alloy cage, outer ring centred

LB

Machined light alloy cage, inner ring centred

LL

Machined light alloy cage, window-type, inner or outer ring centred

ML

Machined brass cage, window-type, inner or outer ring centred

MP

Machined brass cage, window-type, inner or outer ring centred

MR

Machined brass cage, window-type, roller centred

MH

Machined brass cage, inner ring raceway centred

V

Full complement of rollers (no cage)

VH

Full complement of rollers (no cage), self-retaining

SKF suffix - Materials, heat treatment

HA1

Case-hardened inner and outer rings

HA2

Case-hardened outer ring

HA3

Case-hardened inner ring

HA4

Case-hardened inner and outer rings and rollers

HA5

Case-hardened rollers

HA6

Case-hardened outer ring(s) and rollers

HA7

Case-hardened inner ring(s) and rollers

HB1

Bainite-hardened inner and outer rings

HB2

Bainite-hardened outer ring(s)

HB3

Bainite-hardened inner ring

HN1

Inner and outer rings with special surface heat treatment

HN3

Inner ring with special surface heat treatment

L4B

Bearing rings and rollers black oxidized

L5B

Rollers black oxidized

L7B

Inner ring and rollers black oxidized

235220

Case-hardened inner ring with a helical groove in the bore

SKF suffix - Tolerance, clearance, preload, quiet running

P5

Dimensional and geometrical tolerances (tolerances of run-out and orientation) to class P5

P6

Dimensional and geometrical tolerances (tolerances of run-out) to class P6

C1

Radial internal clearance smaller than C2

C2

Radial/Axial internal clearance smaller than Normal

C3

Radial/Axial internal clearance greater than Normal

C4

Radial/Axial internal clearance greater than C3

C5

Radial internal clearance greater than C4

CA

Matched bearing set with small axial internal clearance

GA

Matched bearing set with light preload

CNL

Axial internal clearance in the lower half of the Normal range

C2H

Axial internal clearance in the upper half of the C2 range

C2L

Axial internal clearance in the lower half of the C2 range

CL0

Tolerances to ABMA tolerance class 0 (SKF inch tapered roller bearing)

CL00

Tolerances to ABMA tolerance class 00 (SKF inch tapered roller bearing)

C08

Geometrical tolerances (tolerances of run-out and orientation) to class P5

C083

C08 + C3

C084

C08 + C4

SKF suffix - Bearing sets, matched bearings

DB

Two bearings matched for mounting back-to-back

DF

Two bearings matched for mounting face-to-face

DT

Two bearings matched for mounting in tandem

DR

Set of two matched bearings

TR

Set of three matched bearings

QR

Set of four matched bearings

SKF suffix - Stabilization

S0

Bearing rings heat stabilized for operating temperatures ≤ 150 °C (300 °F)

S1

Bearing rings heat stabilized for operating temperatures ≤ 200 °C (390 °F)

S2

Bearing rings heat stabilized for operating temperatures ≤ 250 °C (480 °F)

S3

Bearing heat stabilized for operating temperatures ≤ 300 °C (570 °F)

SKF suffix - Lubrication

W64

Solid Oil

W33

Annular groove and three lubrication holes in the outer ring

W33X

Annular groove and six lubrication holes in the outer ring

W20

Lubrication holes in the outer ring

SM..

Special grease, two numbers following identify the grease

GEM9

Filled to 70 - 100% with SKF LGHB 2 grease

VT143

Filled to 25 - 45% with SKF LGEP 2 grease

SKF suffix - Other variants

VA947

SKF Food Line bearing made of bearing steel: Blue contact seal made of FDA and EC approved NBR and lubricant (GFQ) registered by NSF as category H1

VP311

SKF Food Line bearing made of stainless steel: Blue contact seal made of FDA approved NBR and lubricant (GFJ) registered by NSF as category H1

VQ658

Quiet running properties

309829

Larger balls

PEX

SKF Explorer bearing, used only when same-sized conventional and SKF Explorer bearings are available

VA301

Bearing for railway vehicle traction motors

VA305

VA301 + special inspection routines

VA350

Bearing for railway axleboxes

VA380

Bearing for railway axleboxes in accordance with EN 12080, class 1

VA3091

VA301 + external surfaces of the outer ring are coated with aluminium oxide

VC025

Bearing with special wear-resistant raceways for applications in heavily contaminated environments

VQ015

Inner ring with crowned raceway for increased permissible misalignment

VA907

Sealed bearing

VJ202

Set of two matched double row bearings

CL7A

Pinion bearing, superseded by CL7C

CL7C

High-performance design

CLN

Tighter tolerances for ring widths and total (abutment) width in accordance with ISO tolerance class 6X

VA405

Bearing for vibratory applications, surface-hardened stamped steel cages

VA406

Same as VA405, but PTFE coated cylindrical inner ring bore

VA944

Bearing for food and beverage applications

VA991

Bearing for high-speed applications

VA9B1

Bearing for continuous caster applications

VG114

Surface-hardened stamped steel cages

VG127

Two separate cages

VE447(E)

Shaft washer with three equally-spaced threaded holes to accommodate hoisting tackle. The E indicates that appropriate eye bolts are supplied with the bearing.

VE710(E)

Housing washer with three equally-spaced threaded holes to accommodate hoisting tackle. The E indicates that appropriate eye bolts are supplied with the bearing.

VU029

Shaft washer modified for applications with small axial clearance