Kaydon part number codes, Reali-Slim® open & sealed bearings Endurakote®-plated bearings Reali-Slim® stainless steel bearings

| Position | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10-13 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nomenclature | Material | Series | Size | Type | Separator | Precision | Internal fit | DFAR compliance | ||

| Example | J | B | 0 | 2 | 0 | C | P | 0 | -USA | |

Kaydon Reali-Slim® open bearings and sealed bearings, stainless steel bearings, and Endurakote® bearings are marked for complete identification with an (8) or (9) digit part number. Positions 1–8 identify materials, size, type, and precision. Position 9 (optional) identifies non-standard internal fit.

Position 1—Material

| Races/balls | Seals, shields | |

|---|---|---|

| A | AISI 52100 Steel | One seal—PTFE |

| B | AISI 52100 Steel | Two seals—PTFE |

| D | AISI 52100 Steel | One shield |

| E | AISI 52100 Steel | Two shields |

| F | AISI 52100 Steel | One seal—Nitrile rubber Lami-seal® |

| G | AISI 52100 Steel | Two seals—Nitrile rubber Lami-seal® |

| H | AISI 52100 Steel | One seal—Nitrile rubber |

| J | AISI 52100 Steel | Two seals—Nitrile rubber |

| K | AISI 52100 Steel | No seals or shields |

| L | AISI 52100 Steel | Two seals & Endurakote® plating |

| M | M-50 Steel | No seals or shields |

| N | AISI 52100 Steel | No seals & Endurakote® plating |

| P | AISI 17-4PH Steel | Ceramic balls |

| Q | AISI 52100 Steel | No shields or seals |

| S | AISI 440C Stainless Steel | No seals or shields |

| T | AISI 440C Stainless Steel | One seal—PTFE |

| U | AISI 440C Stainless Steel | Two seals—PTFE |

| V | AISI 440C Stainless Steel | Two shields |

| W | AISI 440C Stainless Steel | Two seals—Nitrile rubber |

| X | AISI 52100 Steel | Ceramic balls |

| Y | AISI 440C Stainless Steel | Ceramic balls |

| Z | Other |

Position 2—Standard series cross section (inches)

| Radial thickness | Width | |||

|---|---|---|---|---|

| AA | *.187 | x | .187 |  |

| A | .250 | x | .250 |  |

| B | .312 | x | .312 |  |

| C | .375 | x | .375 |  |

| D | .500 | x | .500 |  |

| F | .750 | x | .750 |  |

| G | 1.000 | x | 1.000 |  |

| Radial thickness | Width | |||

|---|---|---|---|---|

| JHA | .187 | x | .250 |  |

| JA | .250 | x | .250 |  |

| JB | .312 | x | .312 |  |

| JU | .500 | x | .375 |  |

| JG | 1.000 | x | 1.000 |  |

| * Smaller section applies when position 3 is alphabetic—see following explanations of positions 3, 4, and 5. | ||||

Positions 3, 4, & 5—Size (bearing bore)

Numeric characters

Nominal bearing bore in inches multiplied by ten

Alphabetic characters

"A" in position 3 in combination with "A" in position 2

denotes .187 x .187 series

"A" in position 3 in combination with "H" in position 2

denotes .187 x .250 series

"A" in position 3 in combination with "S" in position 2

denotes .187 x .312 series

Examples

040 = 4.0" bore

120 = 12.0" bore

400 = 40.0" bore

"10" following "AA" in positions 2 & 3 =

.187 x .187 series with 1.0" bore

"15" following "HA" in positions 2 & 3 =

.187 x .250 series with 1.5" bore

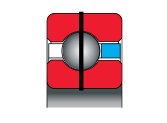

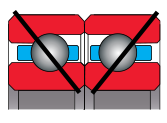

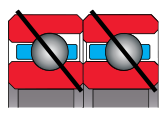

Position 6—Bearing type

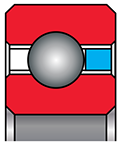

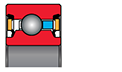

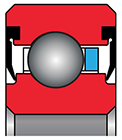

| A | Angular contact single bearing (not ground for universal duplexing) |  |

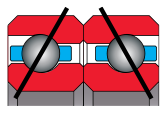

| B | Angular contact pair—duplexed back to back |  |

| C | Radial contact |  |

| F | Angular contact pair—duplexed face to face |  |

| T | Angular contact pair—duplexed tandem |  |

| U | Angular contact single bearing—ground for universal duplexing |  |

| X | Four-point contact |  |

| Z | Other | |

Position 7—Separator

|

|

| C | Non-metallic composite, segmental, "snap-over" type |

| D | Phenolic laminate, one-piece ring "snap-over" type |

| E | Brass, segmental "snap-over" type |

| L | Nylon, one-piece ring "snap-over" type |

| N | Nylon, "snap-over" type |

| P | Standard formed ring "snap-over" type (material—brass or non-metallic composite) |

| T | Stainless steel, formed ring "snap-over" type |

| V | Brass, formed ring, "snap-over" type |

| X | PEEK, one-piece, "snap-over" pocket |

|

|

| G | Nylon one-piece ring, circular pocket |

| H | Phenolic laminate, one-piece ring with circular pockets |

| J | Nylon strip separator, circular pockets |

| K | Phenolic laminate, riveted two-piece ring |

| Q | PEEK, one-piece ring, circular pocket |

| R | Standard formed ring, circular pocket (material—brass or non-metallic composite) |

| U | Stainless steel, formed ring circular pockets |

| Y | Brass, formed ring, circular pockets |

|

|

| M | Formed wire, strip or segmental, "snap-over" type, ball in every pocket |

| W | Formed wire, strip or segmental, "snap-over" type |

|

|

| F | Full complement bearing—no separator |

| S | Helical coil springs |

| Z | Other (toroids, slugs, spacer balls or others available) |

Position 8—Precision

| 0 | Kaydon precision class 1 per ABEC 1F |

| 1 | Kaydon precision class 1 with class 4 runouts |

| 2 | Kaydon precision class 1 with class 6 runouts |

| 3 | Kaydon precision class 3 per ABEC 3F |

| 4 | Kaydon precision class 4 per ABEC 5F |

| 6 | Kaydon precision class 6 per ABEC 7F |

| 8 | Other |

Position 9—Bearing internal fit

| A | .0000 to .0005 clearance |

| B | .0000 to .0010 clearance |

| C | .0005 to .0010 clearance |

| D | .0005 to .0015 clearance |

| E | .0010 to .0020 clearance |

| F | .0015 to .0025 clearance |

| G | .0020 to .0030 clearance |

| H | .0030 to .0040 clearance |

| I | .0040 to .0050 clearance |

| J | .0050 to .0060 clearance |

| K | .0000 to .0005 preload |

| L | .0000 to .0010 preload |

| M | .0005 to .0010 preload |

| N | .0005 to .0015 preload |

| P | .0010 to .0020 preload |

| Q | .0010 to .0015 preload |

| R | .0015 to .0025 preload |

| S | .0020 to .0030 preload |

| Z | Other clearance or preload not specified above |

| Type X or C = diametral preload or clearance Duplexed type A = axial preload or clearance Note: Above internal bearing fits apply to unmounted bearings only. Mounting fits can greatly affect final internal bearing fit. |

|

Position 10–13—DFAR compliance

All Reali-Slim® bearings requiring compliance with Defense Federal Acquisition Regulations (DFAR) "Specialty Metals" and "the Restrictions on Acquisition of Ball and Roller Bearings" clauses will contain '-USA' in positions 10-13. If internal fit is not called out in position 9, it will also contain a dash.