INA axial cylindrical roller bearings are available as:

- single and double row bearings

- individual bearing parts for combination, comprising

- axial cylindrical roller and cage assembly (prefix K)

- housing locating washer (prefix GS)

- shaft locating washer (prefix WS)

- bearing washers (prefix LS, alternatively for shaft and housing locating washer).

INA single and double row axial cylindrical roller bearings are particularly suitable where:

- high axial and shock loads occur in one direction but no radial loads are present

- the load carrying capacity of the corresponding axial deep groove ball bearings is no longer adequate (in this case, bearings of series 811 and 812 are especially suitable)

- the bearing arrangement must have very high axial rigidity

- the axial space available is very small

- the bearing arrangement can be configured, where the axial space is very small, as a direct bearing arrangement

- this type of INA bearing parts can or must be mounted separately

- the bearing arrangement is not configured in itself but, for cost reasons, ready-to-fit standard bearings are to be used.

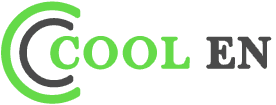

Axial cylindrical roller bearing and axial ball bearing – comparison of load carrying capacity and design envelope

- Fa = axial load

- Ca = basic dynamic load rating

- Dw = roller diameter

- T = axial section height of axial deep groove ball bearing

INA axial cylindrical roller bearing

INA axial cylindrical roller bearings are part of the group of axial roller bearings. In contrast to the ball, the roller has a larger contact area perpendicular to the roller axis. As a result, it can transmit higher forces, has greater rigidity and allows smaller rolling element diameters under the same load. The single and double row bearings comprise flat, ribless washers (housing and shaft locating washers) between which axial cylindrical roller and cage assemblies are arranged. Their axial section height T corresponds only to the diameter of the rollers plus the thickness of the washers. Due to this design, INA bearings are particularly small in axial height. The axial cages are made from brass or plastic and are fitted with one or two rows of cylindrical rollers. Since sliding occurs towards the ends of the rollers during rolling of the rolling elements and this increases with the length of the roller, bearings with a wide cross-section have several short rollers arranged adjacent to each other, e.g. double row designs.

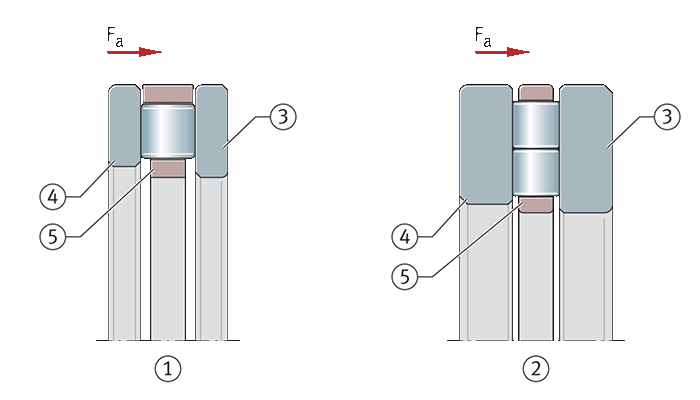

INA Axial cylindrical roller bearings

Fa = axial load

- Single row bearing

- Double row bearing

- Shaft locating washer

- Housing locating washer

- Axial cylindrical roller and cage assembly

Rollers with profiled ends increase the operating life of the bearings

The cylindrical rollers have profiled ends, i.e. they have a slight lateral curvature towards the ends. This modified line contact between the rollers and raceways prevents damaging edge stresses. This in turn has a positive effect on the operating life of the bearings.

Roller and cage assembly and bearing washers are also available individually

The bearing parts for axial cylindrical roller bearings are also available individually. INA Axial cylindrical roller and cage assemblies (without shaft and housing locating washers) are suitable, for example, for bearing arrangements with very small axial design space.

INA axial cylindrical roller and cage assemblies

The cage assemblies comprise axial cages and one or two rows of cylindrical rollers. They have a particularly small axial section height and high axial load carrying capacity. The cages are made from polyamide or brass and are guided on the shaft.

INA axial cylindrical roller and cage assemblies are generally combined with one housing locating washer and one shaft locating washer. If they are to be used directly – i.e. without axial bearing washers – in the adjacent construction, the raceway for the rollers must be produced as a rolling bearing raceway. It is also possible to use two shaft locating washers or two housing locating washers in combination with one axial cylindrical roller and cage assembly.

INA axial bearing washers

Housing locating washers are externally centred, shaft locating washers are internally centred. They must be used if the adjacent construction cannot be used as a raceway for the rolling elements. The washers are made from through hardening rolling bearing steel. The bore and outside diameter are precision machined, the raceways are ground to high accuracy.

Bearing washers are suitable for use as a housing or shaft locating washer. They are used in applications that do not require precise centring of the axial bearing washers. The raceway of the bearing washers is hardened and ground. The bearing washers are suitable for axial cylindrical roller and cage assemblies K811 and axial needle roller and cage assemblies AXK.

Lubrication

INA axial cylindrical roller bearings are not greased. The bearings must be lubricated with oil or grease.

When using bearings with plastic cages, compatibility between the lubricant and the cage material must be ensured if synthetic oils, lubricating greases with a synthetic oil base or lubricants containing a high proportion of EP additives are used.

Internal clearance

In the case of INA axial cylindrical roller bearings, the internal clearance (axial clearance) is only achieved when INA bearings are mounted. The requisite axial clearance of the bearing arrangement is dependent on the application and must take account of the conditions in the bearing arrangement while warm from operation and subjected to load.

If axial cylindrical roller bearings are subjected to vibrations while under predominantly static load, for example, they must be lightly preloaded. Preload can be applied, for example, using calibrated sheets (shims). Other suitable means include shaft nuts, disc springs, etc. It must always be ensured that no slippage occurs in operation between the rolling elements and raceways. It must also be ensured that the preload does not exceed the optimum value, otherwise there will be an increase in friction and therefore in heat generation in the bearing. These will both have a negative effect on the operating life of the bearings.

Suffixes

For INA bearing designation system, Please refer to bearings nomenclature.

| Suffix | Description |

|---|---|

| M | Solid brass cage |

| TV | Solid cage made from glass fibre reinforced polyamide PA66 |

| P5 | High dimensional, geometrical and running accuracy |

The designation of INA bearings follows a set model. Examples

INA single row axial cylindrical roller bearing

812 30 - M

- 812: Bearing series

- 30: Bore code

- M: suffixes, Solid brass cage

INA double row axial cylindrical roller bearing

893 10 - TV

- 893: Bearing series

- 10: Bore code

- TV: suffixes, Solid cage made from glass fibre reinforced polyamide PA66