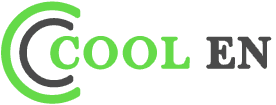

Mounting Orientation

THK LM Guide can be mounted in the following five orientations.

If the mounting orientation is other than horizontal use, the lubricant may not reach the raceway completely.

Be sure to let THK know the installation direction and the exact position in each LM block where the grease nipple or the piping joint should be attached.

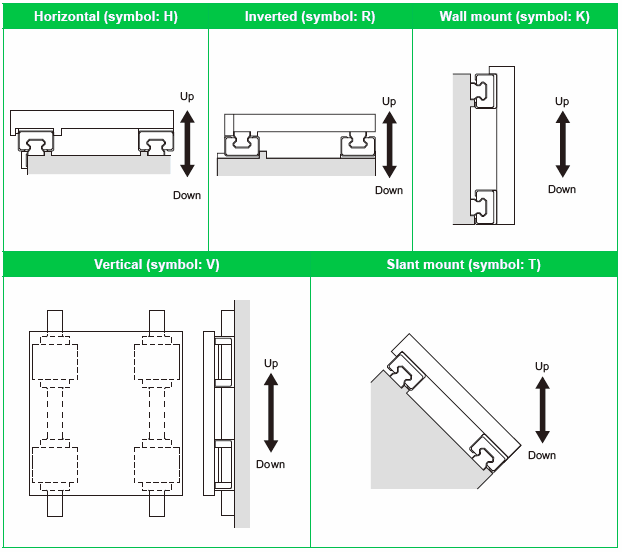

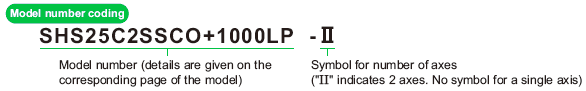

Symbol for Number of Axes

If two or more units of the THK LM Guide are parallelly used in combination on the same plane, specify the number of the LM rails (symbol for number of axes) used in combination in advance.

Service environment

Lubrication

When using an THK LM system, it is necessary to provide eff ective lubrication. Without lubrication, the rolling elements or the raceway may be worn faster and the service life may be shortened.

A lubricant has eff ects such as the following.

- Minimizes friction in moving elements to prevent seizure and reduce wear.

- Forms an oil film on the raceway to decrease stress acting on the surface and extend rolling fatigue life.

- Covers the metal surface to prevent rust formation.

To fully bring out the THK LM Guide’s functions, it is necessary to provide lubrication according to the conditions.

If the mounting orientation is other than horizontal use, the lubricant may not reach the raceway completely.

Be sure to let THK know the mounting orientation and the exact position in each LM block where the grease nipple or the piping joint should be attached.

Even with an THK LM Guide with seals, the internal lubricant gradually seeps out during operation. Therefore, the system needs to be lubricated at an appropriate interval according to the conditions.

Corrosion Prevention

Determining a Material

Any LM system requires a material that meets the environments. For use in environments where corrosion resistance is required, some LM system models can use martensite stainless steel. (Martensite stainless steel can be used for LM Guide models SHS, SSR, SHW, SRS, HSR, SR, HRW, RSX, RSR and HR.)

Surface Treatment

The surfaces of the rails and shafts of LM systems can be treated for anti-corrosive or aesthetic purposes. THK off ers THK-AP treatment, which is the optimum surface treatment for LM systems.

Contamination Protection

When foreign material enters an LM system, it will cause abnormal wear or shorten the service life, and it is necessary to prevent foreign material from entering the system. When entrance of foreign material is predicted, it is important to select an eff ective sealing device or dust-control device that meets the environment conditions.

THK offers contamination protection accessories for LM Guides by model number, such as end seals made of special synthetic rubber with high wear resistance, and side seals and inner seals for further increasing dust-prevention eff ect.

In addition, for locations with adverse environment, Laminated Contact Scraper LaCS and dedicated bellows are available by model number. Also, THK off ers dedicated caps for LM rail mounting holes, designed to prevent cutting chips from entering the LM rail mounting holes. When it is required to provide contamination protection for a Ball Screw in an environment exposed to cutting chips and moisture, we recommend using a telescopic cover that protects the whole system or a large bellows.