Bearing fits can be selected by recommended fits. These recommendations will provide adequate solutions for the majority of applications. However, they don't cover all details of a specific application, and so you should consider the following topics when selecting bearing fits.

- Shaft and housing material, wall thickness, finished surface accuracy, etc.

- Machinery operating conditions (nature and magnitude of load, rotational speed, temperature, etc.)

Load conditions and fits

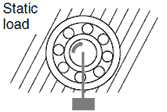

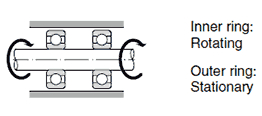

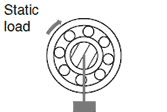

For raceways under rotating loads, a tight fit is necessary. "Raceways under rotating loads" refers to raceways receiving loads rotating relative to their radial direction. For raceways under static loads, on the other hand, a loose fit is sufficient.

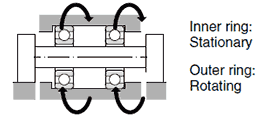

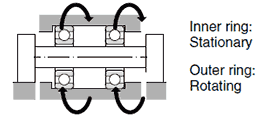

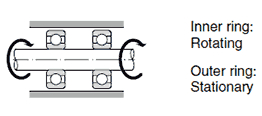

| Illustration | Bearing rotation | Ring load | Fit |

|---|---|---|---|

|  | Rotating inner ring load Static outer ring load | Inner ring: Tight fit Outer ring: Loose fit |

|  | ||

|  | Static inner ring load Rotating outer ring load | Inner ring: Loose fit Outer ring: Tight fit |

|  | ||

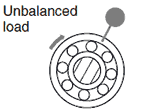

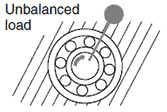

Inner ring: Rotation or Stationary Outer ring: Rotation or stationary | Direction of load indeterminate | Inner ring: Tight fit Outer ring: Tight fit |

Rotating loads occur where either the bearing ring or the applied load is stationary while the other rotates. A bearing ring mounted with a loose fit will creep on its seat when subjected to a rotating load, and this can lead to fretting corrosion and eventually wear. To prevent this from happening, an adequate interference fit, between the ring subjected to rotating load and its seat, is required.

For the purpose of selecting fits, loads that oscillate (such as loads acting on connecting rod bearings) are considered to be rotating loads.

Static loads occur where both the bearing ring and the applied load are stationary or both are rotating at the same speed. Under these conditions, a bearing ring normally does not creep and there is no risk of fretting corrosion or wear. In this case, the ring does not need to have an interference fit.

Direction of load indeterminate refers to variable or alternating external loads, sudden load peaks, vibration or unbalanced loads in high-speed applications. These give rise to changes in the direction of load, which cannot be accurately described. Where the direction of load is indeterminate and particularly where heavy loads are involved, there is a risk of fretting corrosion or wear. You should use an interference fit for both rings. The same fit as for a rotating load is normally suitable.

Where the outer ring should be able to move axially in its housing, a loose fit must be used. However, a loose fit can result in housing wear. Where this cannot be tolerated, either protect the bearing seat surface or select a bearing that accommodates the axial displacement within itself (cylindrical roller, needle roller bearing). These bearings can be mounted with an interference fit for both rings.

For non-separable bearings, such as deep groove ball bearings, it is generally recommended that either the inner ring or outer ring be given a loose fit.

Interference minimum and maximum values

The following points should be considered when it is necessary to calculate the interference for an application:

- In calculating the minimum required amount of interference keep in mind that:

- interference is reduced by radial loads

- interference is reduced by differences between bearing temperature and ambient temperature

- interference is reduced by variation of fitting surfaces

- The upper limit value should not exceed 1/1000 of the shaft diameter.

Required interference calculations are shown below.

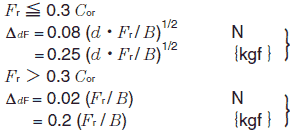

Radial loads and required interference

Interference of the inner ring and shaft decreases when a radial load is applied to the bearing. The interference required to secure effective interference is expressed by formulae

Where,

- ΔdF: Required effective interference according to radial load μm

- d: Bearing bore diameter mm

- B: Inner ring width mm

- Fr: Radial load N {kgf}

- C0r: Basic static load rating N {kgf}

Temperature difference and required interference

Interference between inner rings and steel shafts is reduced as a result of temperature increases (difference between bearing temperature and ambient temperature, ΔT) caused by bearing rotation. Calculation of the minimum required amount of interference in such cases is shown in formula

ΔdT = 0.0015 * d * ΔT

Where,

- ΔdT: Required effective interference for temperature difference μm

- ΔT: Difference between bearing temperature and ambient temperature °C

- d: Bearing bore diameter mm

Fitting surface variation and required interference

Interference decreases because the fitting surface is smoothened by fitting (surface roughness is reduced). The amount the interference decreases depends on roughness of the fitting surface. It is generally necessary to anticipate the following decrease in interference.

- For ground shafts: 1.0 ~ 2.5μm

- For lathed shafts: 5.0 ~ 7.0μm

Maximum interference

When bearing rings are installed with an interference fit, tension or compression stress may occur along their raceways. If interference is too great, this may cause damage to the rings and reduce bearing life. You should try to obtain the previously described upper limit.

Other details

(1) Tight interference fits are recommended for,

- Operating conditions with large vibration or shock loads

- Applications using hollow shafts or housings with thin walls

- Applications using housings made of light alloys or plastic

(2) Small interference fits are preferable for,

- Applications requiring high running accuracy

- Applications using small sized bearings or thin walled bearings

(3) Consideration must also be given to the fact that fit selection will effect bearing clearance selection.